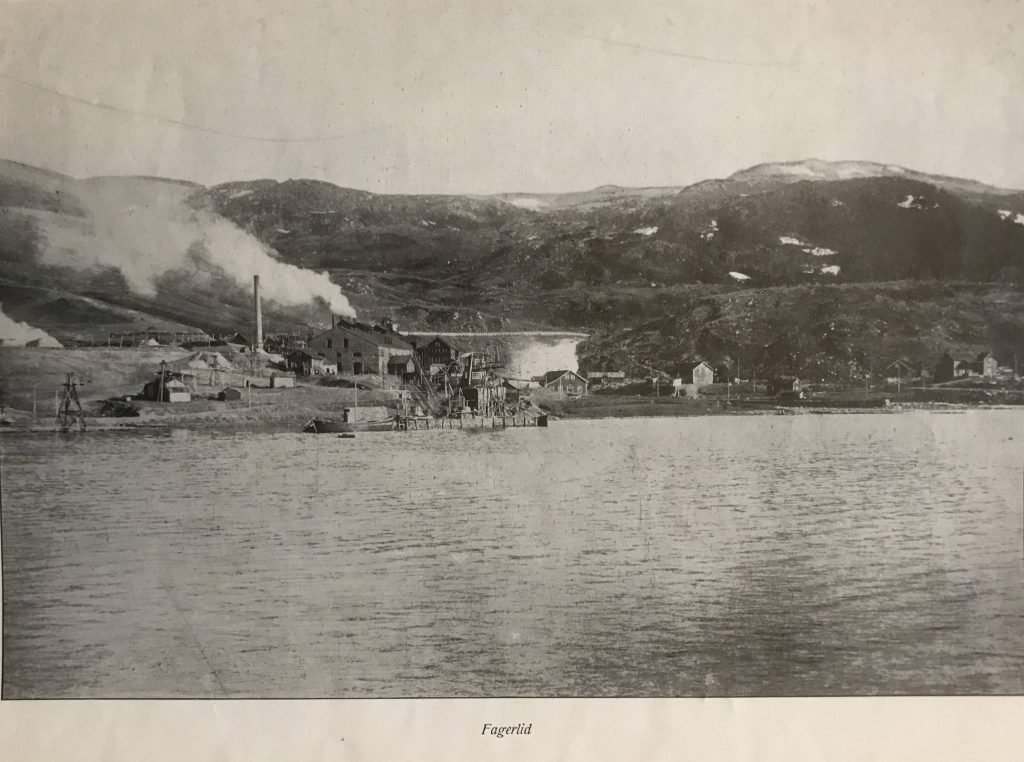

Consul Persson, owner and manager of the copper plant in Helsingborg (Helsingborg kopparverk), secured ownership of the sulphate mines in 1886 with the intention of acquiring a stable Norwegian supplier for the large superphosphate and sulfuric acid factory, which he established under the direction of the “Skenska Superphosphate and Sulphuric Acid Factory” in Helsingborg. The company took over the mines in Sulitjelma in 1889 and carried on extensive investigations. In 1891, the mining company “Sulitjelma Aktiebolag), with headquarters in Helsingborg, was founded. The expansion of the transport network began on a large scale, and several main pits were put into operation; In Fagerlid, the extraction, smelting hut and power plant were built, and a mining community was created.

“Sulitjelma Aktiengesellschaft” sold two products: pure gravel or export gravel, and from 1896 so-called bessemer copper or copper concentrate. Almost everything from the export gravel produced went to Swedish and Danish sulphuric acid factories for the production of sulphuric acid and sulphide liquor.

Knudsen’s contribution in Sulitjelma can be illuminated by a closer look at the procedure in the separator plant and the smelting smelter. The separation of the ore began with the separation or manual sorting, which took place in the separator house at the individual pits. The ore was divided into three categories: pure copper gravel, pure sulfur gravel and mixed ore.

The copper gravel was brought to the smelter for roasting and melting, while the sulfur gravel was exported to Helsingborg without further processing. The mixed ore was treated in the laundry, where sulfur gravel, copper gravel and rock were separated. The copper gravel or iron ore consisted of copper, iron and sulfur (CuFeS2), and the aim of further processing was to remove the sulfur and iron. The first part of this process was the roasting of the ore.

Roasting was aimed at reducing the sulfur content and oxidizing part of the iron. The ore was roasted on piled birch wood logs. The second part of the process was the melting of the roasted good in a smelting furnace, and the production of copper matte. The melting took place in a water cap furnace or a so-called “waterjacket” oven, a water-cooled shaft furnace, which was heated by the combustion of coal or coke. The liquid mass from the furnace was transferred to a larger container, where it separated in the heavier copper matte, which sank to the ground, and a lighter slag that rose upwards.

The copper matte contained about 35-40% copper. In 1897, ten years after the copper plant in Røros, the Bessemer process was introduced in Sulitjelma in the smelter. This replaced the following three processes with the copper stone, all of which required the supply of energy in the form of heat. The Bessemer process was carried out in two stages in a Bessemer converter. In the first step, the so-called slag bubbles, the iron in the copper matte was removed. The liquid copper matte was converted into a converter, and if the quartz content in the melt mass was not high enough, extra quartz was added. By blowing compressed air into the melting bath, the iron became bound to the oxygen in the air, and oxygen and silicon in the quartz, and it rose to the surface as a slag. The slag was poured out, and a mixture of copper and sulfur, called white metal, remained.

The next step was the removal of sulfur, the so-called copper bubbles, wherecompressed air was blown through the white metal. The sulfur combined with oxygen and evaporated as sulfur smoke (SO2). The final product in this process was blister copper with a copper content of about 99%. The rest were gold, silver, as well as small remnants of iron, sulfur and oxygen. From 1897, blister copper was produced in Sulitjelma after the Bessemer process had been introduced at the Fagerli smelter. The old wooden smelter from 1894 burned down in 1898, and a new and larger stone smelter was built in 1899. This had four copper stone furnaces and two Bessemer converters.

The development of the smelting plant in Sulitjelma became Knudsen’s matter of the heart. A growing problem was rising production costs in the smelter. Large quantities of coke were consumed to melt the copper stone, and the price of coke rose. Fuel shortages and falling copper prices necessitated savings. Knudsen began the first experiments in the smelter in 1902. His idea was to replace the pre-melting of the ore in the manhole furnace, which consumed a lot of coke, with melting in a movable converter, in which the sulfur and the iron of the ore formed the fuel. Others had tried this method, such as John Holloway in England in the 1870s, but with poor results. In its specially shaped oven of seven tons, Knudsen was able to carry out the process with a coke consumption of only 1 to 1.5%. One of the problems he encountered was that the furnace cladding made of ordinary refractory brick reacted with the melting bath, and corroded within a short time. Due to the use of magnesite, the cladding lasted longer. It also turned out that the stone was smashed to pieces by the jets for air supply. This was solved by the purchase of new compressors, which ensured a higher air pressure during injection into the Knudsen furnace. Cooling the molten mass in the air nozzles was also a problem. This was solved by modifying the upper shape of the furnace, as well as using reduced vacuum in the compressed air. By 1904, a process and a specially built Knudsen oven had been produced, which had a satisfactory effect. The necessary changes were made in the smelter and a new pyrite furnace of 12 tons with tipping machine and large compressor was ordered. In 1905 the equipment was in place and in operation. In 1906 a new and larger pyrite converter of 25 tons was installed. The pyrite melting, orKnudsen process, reduced coke and time consumption, and gave a higher copper yield. Time savings in the same category as “interest income”, according to Knudsen. And the total melting costs were only one third of the cost of roasting and pre-melting in the shaft furnace.

The Knudsen process replaced both time-consuming roasting and costly melting of copper matte. The next problem was how to create a poor slag. It turned out that the copper content in the slag was too high. At first, an attempt was made to transfer the finished melting material from the Knudsen furnace to a flame furnace, which was built in 1906. The mass was kept liquid here for a while in order to better separate the slag from the copper matte. The furnace was taken out of service the following year because the operation became too expensive and frequent repairs were necessary. Instead, the slag was poured into cast iron slag vessels, which better separated slag and copper matte. The vessels with the copper matte were emptied into the Manhès converters, after which one could directly blow “copper”; i.e. the second part of the Bessemer process could be carried out.

In the smelter, copper matte from the pyrite smelting was processed into blister copper with 99.20% Cu. In Sulitjelma, where the ore has a relatively small copper content, they worked to obtain a rich copper matte suitable for the Bessemer process, and therefore both processes were kept in the smelter.

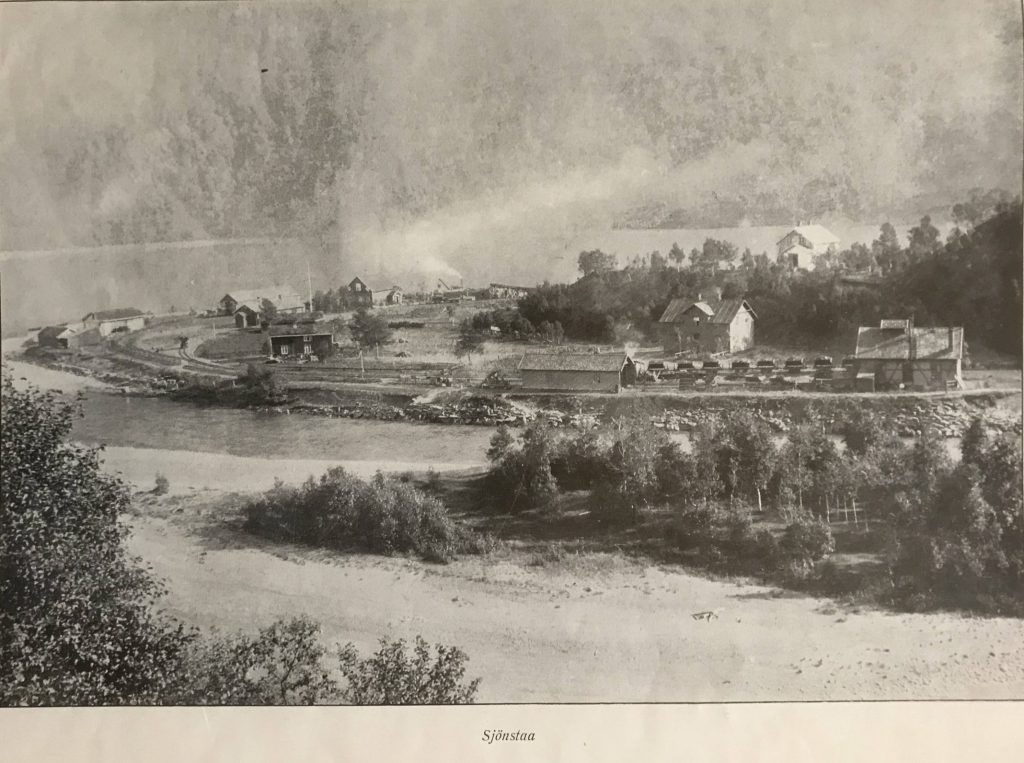

Director Knudsen also stood for an important extension of the separation plant. The low-percentage copper ore, which remained after the separation by hand, was crushed in the rolling mill, and then went to the setting machines, washing tables and pointed boxes. Although the laundry in Sandnes was “first-class, well-designed and of excellent technical ability and care,” the loss of copper in the end of the wet cut was very high. This was based on the fact that the copper gravel was loose and brittle in its consistency. The finish probably contained 1% copper, large amounts of sulfur gravel and some magnetite, and became diluted in water.

In order to extract copper from this sludge, an Elmore plant with 12 appliances was built in 1909. Elmore’s vacuum process was the first sulphide flotation using oil. The Elmore brothers’ vacuum flotation machine was patented in 1904. The process was based in all simplicity on the fact that the inside of the machine was placed under vacuum. The turbidity was sucked into the machine by a central pipe. With a suction height of six meters, the air dissolved in the turbidity was excreted as bubbles. The bubbles with aerophilic minerals were lifted into an overflow by the turbidity. To keep the machine under vacuum, the overflow went through a nine-metre-long downpipe, usually lowered under water. The buildings for this type of complex were often over 15 meters high. The Plant in Sulitjelma was the largest Elmore plant in Europe, and the longest in operation (until 1920). With this plant old outlet could be used, and outlet could be exploited from the main laundry. On the basis of discharge and sludge, low percentages (from 6 to 11%) were copper concentrate. This was either exported or melted down in the hut. With the fine-grained Elmore concentrate, a new product was obtained for melting in the hut. The Elmore concentrate could not be fed directly to the Knudsen oven, but had to be roasted before melting. A briquette plant was purchased and the briquettes were then to be treated in the Knudsen oven, but this did not work as intended. The engineer Jens Westly, head of the melting hut in Sulitjelma, then invented his own method for the direct injection of dry Elmore concentrate into the melting mass in the furnace. The Elmore plant was gradually expanded to 18 units, and from 1910 the Elmore laundry gained about 1000 tons of copper a year from the departure of the laundry, which would otherwise have been considered worthless. The Elmore plant stood for a modern approach of marginal mineral extraction and advanced industrialization of the extraction process.